Prefabrication

We're redefining building efficiency with high-performance off-site panelized construction.

Krivaja High-Performance Prefabrication

We proudly stand as Southeast Europe's best and most experienced prefab manufacturer. With over 70 years of specialization in prefab manufacturing, our legacy speaks for itself.

Operating on a global scale, we appreciate the diversity of local requirements and have meticulously structured our engineering and production processes for maximum adaptability to varying global regulations and standards. Our expansive portfolio ranges from large-scale commercial developments to charming private residences. Regardless of the project's scale, we approach it with unwavering dedication and professionalism.

Our prefab system is characterized by fully customizable components that seamlessly integrate into a wide range of construction projects. Backed by international certifications such as CE and ETA, and bolstered by Europe’s leading material suppliers and brands, our structures stand as a testament to top-notch engineering.

Distinguished by durability, cost-effectiveness, energy efficiency, rigorous quality control measures, and affordability, our prefabricated construction excels in thermal insulation, leading to reduced maintenance and heating expenses. Furthermore, this construction method enables rapid assembly and boasts impressive resistance to fires, floods, and seismic activities.

Our ultra-precise offsite fabrication streamlines the entire process, making it not only fast but also remarkably stress-free and seamless. Our dedicated team takes pride in working on projects of all sizes, collaborating closely with homeowners, architects, general contractors, and others to create vibrant, enduring, and sustainable buildings.

Drawing upon our extensive past, our dedication to sustainability, our relentless pursuit of quality, and our unmatched flexibility, we can confidently say that when it comes to construction, we can do anything.

Discover our variety of wall options. Beyond these, we're capable of creating walls custom-made to your precise specifications.

Walls

SiliCor

StoneCor

WoodCor

Product Details

Details

Technical Specifications

Specifications

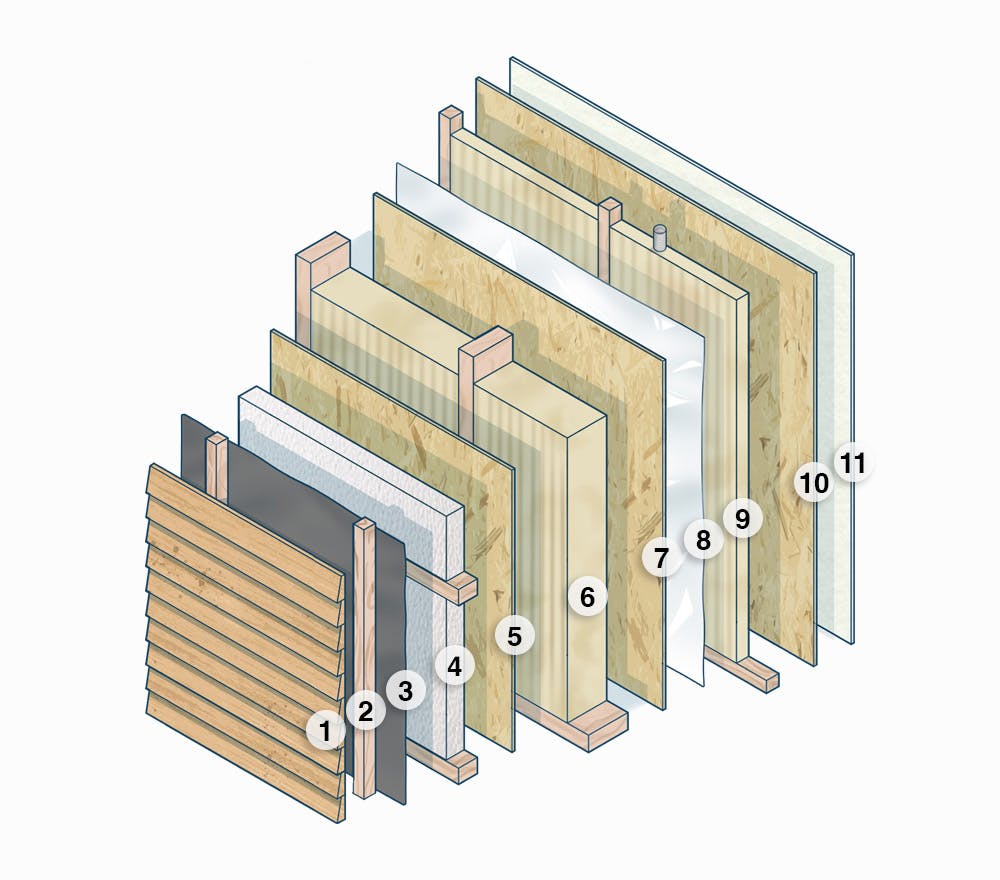

The prefab wall is constructed with a multilayer composition that includes EPS for exterior thermal insulation and a Glass Mineral Wool frame for additional thermal and sound insulation. The total width of the wall assembly measures 389 mm.

Uw = 0.15 W/(m²K)

Rw = 54 dB

REI = 60 min

Width = 389 mm

Why Krivaja Prefab

Bespoke solution

Engineered to order, our prefab systems offer unparalleled customization options. With near infinite variations available in our wall and roof systems, you get to select the thickness, insulation type, boards, and finish that perfectly fits your project.

Engineering Excellence

Our engineering team possesses extensive knowledge of prefabricated construction techniques, delivering structurally sound and efficiently designed buildings. We can turn almost any architectural design into a prefab-ready plan, enabling you to get the building you want with the benefits of prefabricated construction.

Complete Package

We stand out as one of the few prefab manufacturers capable of providing an all-inclusive in-house service that encompasses engineering, installation, and production of prefab construction, as well as full-scale joinery and engineered wood. We maintain total oversight from inception to completion

Premium Products

Components that we don't produce in-house are sourced from industry leaders such as James Hardie, Egger, Rockwool, Sto, and more. Through these partnerships, we ensure that every element of our prefab structures is of the utmost quality.

Proven Heritage

Boasting over 70 years of experience, our heritage speaks volumes. We don't just do prefab; we pioneered it. Our legacy is a testament to our commitment to excellence and innovation in the field of construction.

Speedy Precision

Off-site construction streamlines building projects by merging simultaneous processes in a controlled environment, eliminating weather-related delays and ensuring precise, efficient production. This approach guarantees faster, more predictable timelines, making it a superior choice for modern construction needs.

Sustainable Approach

We prioritize sustainability with top-quality, FSC-certified wood from our mill and trusted European sources. Committed to zero waste, we maximize every wood piece, and our construction system ensures energy efficiency, meeting modern standards.

Assembly Assurance

Specializing in meticulous prefab construction, our team delivers unparalleled results. For clients with specialized teams, we provide an expert instructor to ensure optimal assembly and erection of prefab buildings, guaranteeing efficiency and precision throughout the construction process.

Bespoke solution

Engineered to order, our prefab systems offer unparalleled customization options. With near infinite variations available in our wall and roof systems, you get to select the thickness, insulation type, boards, and finish that perfectly fits your project.

Complete Package

We stand out as one of the few prefab manufacturers capable of providing an all-inclusive in-house service that encompasses engineering, installation, and production of prefab construction, as well as full-scale joinery and engineered wood. We maintain total oversight from inception to completion

Proven Heritage

Boasting over 70 years of experience, our heritage speaks volumes. We don't just do prefab; we pioneered it. Our legacy is a testament to our commitment to excellence and innovation in the field of construction.

Sustainable Approach

We prioritize sustainability with top-quality, FSC-certified wood from our mill and trusted European sources. Committed to zero waste, we maximize every wood piece, and our construction system ensures energy efficiency, meeting modern standards.

Engineering Excellence

Our engineering team possesses extensive knowledge of prefabricated construction techniques, delivering structurally sound and efficiently designed buildings. We can turn almost any architectural design into a prefab-ready plan, enabling you to get the building you want with the benefits of prefabricated construction.

Premium Products

Components that we don't produce in-house are sourced from industry leaders such as James Hardie, Egger, Rockwool, Sto, and more. Through these partnerships, we ensure that every element of our prefab structures is of the utmost quality.

Speedy Precision

Off-site construction streamlines building projects by merging simultaneous processes in a controlled environment, eliminating weather-related delays and ensuring precise, efficient production. This approach guarantees faster, more predictable timelines, making it a superior choice for modern construction needs.

Assembly Assurance

Specializing in meticulous prefab construction, our team delivers unparalleled results. For clients with specialized teams, we provide an expert instructor to ensure optimal assembly and erection of prefab buildings, guaranteeing efficiency and precision throughout the construction process.

Browse our catalogue of designer-made houses for inspiration, and let us tailor a bespoke design to your unique needs.

Additional information

What is generally included in the standard offer?

Included in the Offer Price:

- Comprehensive Project Documentation covering electrical, plumbing, static, and prefabricated elements workshop drawings.

- Production: All wall components (interior and exterior), floor elements, and roof and ceiling construction are produced according to the chosen specification, complete with accompanying insulation and boards.

- Utility Installations: Embedded electrical and plumbing setups in prefabricated wall elements.

- Roof Treatment & Finish:

- Varnish protection for visible roof parts, fascia boards, and rafters.

- Final roof finishing, including tiles, metal sheets, etc., as specified in the offer.

- Full Installation Services which encompass:

- Hydro insulation for internal and external walls.

- Wall components, roof, and ceiling setup.

- Exterior and interior joinery fitting (RAL standards).

- Facade cladding/finishing.

- Internal linings for walls/ceilings.

- Staircase and wooden fence assembly.

- Foil connections (ETA standards).

- Fixings & Fasteners: All necessary components such as anchors, L-profiles, and Fisher screws are included to ensure a secure and seamless assembly.

- Doors & Windows: Provision and fitting of windows, entrance doors, and internal doors as detailed in the offer and drawings.

- Additional Architectural Features:

- Complete wooden staircase with handles and rails.

- Painted and protected external wooden terrace rail with vertical spindles.

What is expected of the buyer?

Buyer's Obligations:

1. Project Management:

- Project Documentation: Actively review and provide timely approval for project documentation to ensure smooth execution.

- Prompt Engagement: Provide timely responses and feedback to any project-related queries or decisions.

- Third-party Liaison: Coordinate with any third-party vendors or consultants who might be involved in the project.

2. Site Preparation & Infrastructure:

- Foundation & Setup: Lay sturdy concrete foundations for the assembly of prefabricated components, ensuring dilatation tolerance of ±2cm for optimal fit and integrity. Ensure the construction site is prepared with scaffolding and make water and electricity readily available on-site for seamless construction operations.

- Equipment & Facilities: Provision of crane facilities to aid in the unloading and assembling of prefabricated components.

3. Logistics & Worker Support:

- Material Management: Handle transportation of materials from the factory to the construction site efficiently and ensure their protection on-site.

- Worker Accommodations & Transport: Organize comfortable accommodation and efficient local transportation for construction workers and instructors.

4. Documentation & Financial Obligations:

- Documentation & Permissions: Provide all essential paperwork, licenses, and authorizations to ensure smooth operations and adherence to local guidelines.

Financial Responsibilities: Ensure punctual payment as per agreed terms to facilitate uninterrupted project flow.

What is the price per square meter?

The pricing of prefabricated houses is a complex process and does not solely depend on the total area of the home. Instead, it's more intricately determined by a detailed cost sheet, which breaks down the various elements contributing to the final price. This cost sheet itemizes the amounts of materials used and multiplies them by their respective unit prices. The unit prices, in turn, are influenced by the specific types of materials chosen to be installed in the house.

The architectural design of the house plays a significant role in the overall cost. A more complex or intricate design might require specialized materials or unique construction techniques that could raise the price. Similarly, the types of materials selected—whether premium-grade, eco-friendly, or basic—can substantially influence the final price tag. Numerous elements can influence the cost. Hence, we provide free personalized price calculations for each project's specific needs.

What is the timeframe necessary to construct a prefab home?

After signing the contract with the customer, the cooperation on workshop drawings typically takes less than a month to finalize. Once these drawings are approved and signed off, production generally spans between 60 to 80 days. Following this production phase, there's the added shipping duration to the construction site.

For a prefab building approximately 150 m² in size and built to a high Rohbau standard, the assembly duration is estimated between 25 to 30 days. Notably, the core assembly — which encompasses the erection of walls, setting up intermediate floor structures, and installing roof panels — is accomplished in less than four days. However, it's important to note that the exact timeframe can fluctuate based on the intricacy and specific design of the house. Additionally, weather conditions and the location of the construction site can also influence the overall timeframe.

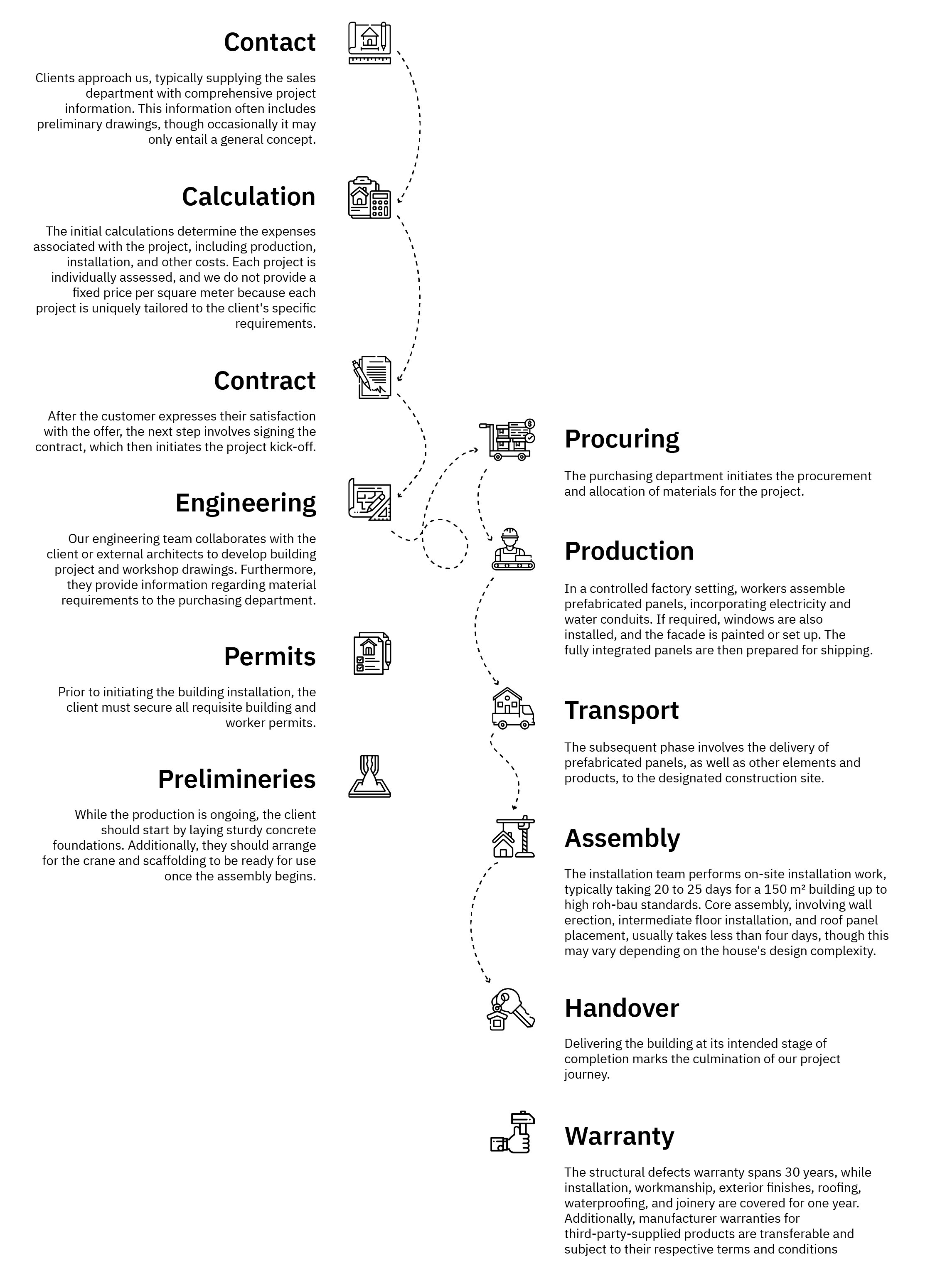

What is the typical journey for acquiring a prefabricated building?

Can you do turnkey project?

No, generally, we do not undertake turnkey projects. While we have completed some in the past and may consider them again in the future, our primary focus is on prefab construction, engineered wood, and joinery. We believe in specializing in our areas of expertise and prefer to leave final furnishings and similar tasks to those who specialize in that field. This approach allows us to maintain high standards in the services we excel at.

Do you undertake building projects in [specific country]?

Probably! We enjoy traveling and in the past decade, we've worked in over 30 countries. However, it's important to remember that each country has its own regulations and specific requirements. While we'd love to give a definitive 'yes', the reality is a bit more complex. We encourage you to contact us, and we'll do our utmost to accommodate your needs.

Let’s embark on the journey to create a space that reflects your unique style and needs.